Every shop wants predictable production and machines that run the way they should. Annual preventative maintenance is one of the simplest ways to protect uptime and keep your CNC equipment cutting accurately year after year. When paired with a full Total Productive Maintenance inspection, you get the deepest look at machine health so you can catch problems early instead of losing hours to unexpected breakdowns.

Why Annual PM Matters

Annual PM gives technicians a chance to inspect wear points before they become failure points. This routine service lowers downtime risk, preserves accuracy across milling and turning platforms, and helps extend the working life of every machine tool in the shop. Shops that stay on a yearly PM schedule usually see fewer emergency calls and more predictable throughput because the machines aren’t drifting out of spec.

What TPM Adds on Top

A Total Productive Maintenance inspection takes the process even further. TPM covers the full system, including hydraulics, lubrication, cooling circuits, electrical components and machine geometry. This broad assessment helps you understand true performance health instead of guessing based on sounds or surface finish.

What Technicians Check

A TPM checklist gives your machines a complete review. Key steps include:

- Lubrication system inspection and verification of proper flow

- Hydraulic pressures, hoses and pump condition

- Coolant delivery, filtration and heat exchanger performance

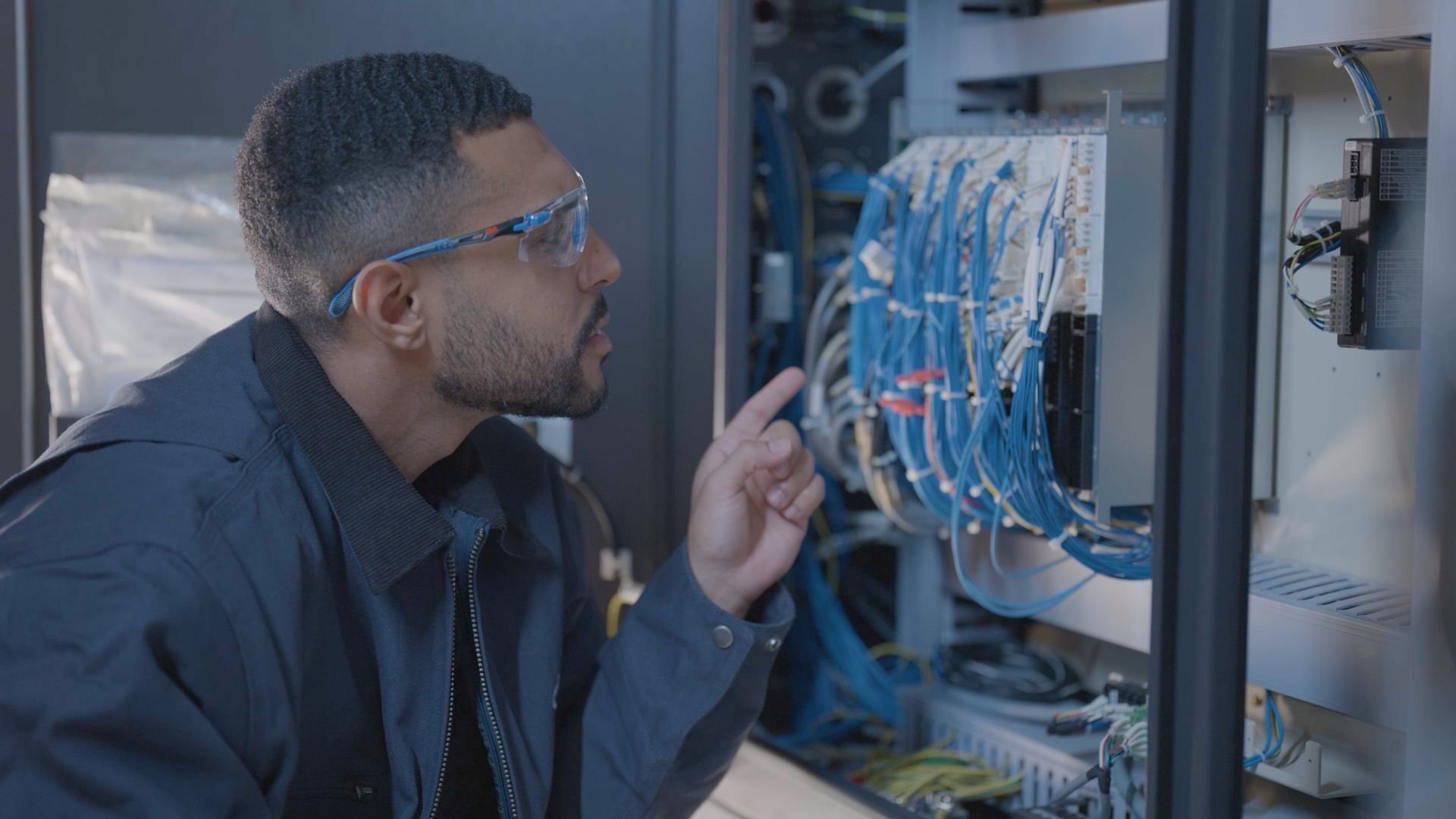

- Electrical cabinet cleaning, wiring condition and sensor checks

- Geometry verification with parallel and perpendicular checks

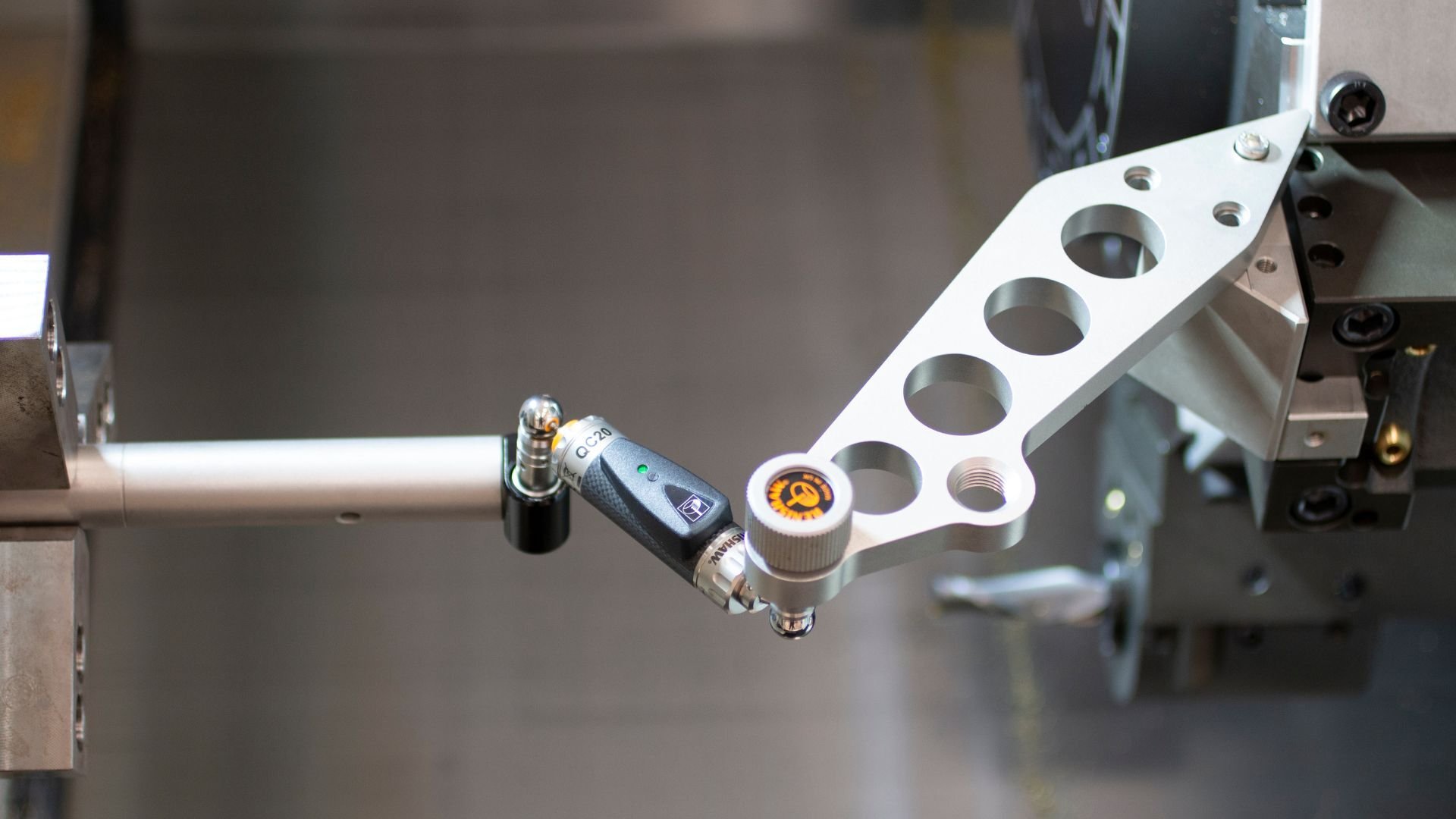

- Spindle runout and pull force testing on machining centers and lathes

Deep Cleaning and Component Replacement

PM also includes cleaning and replacement of filters across tanks, motors, heat exchangers and drive units. These areas collect fines, sludge and heat buildup over time. Cleaning restores proper cooling and lubrication, which helps stabilize performance during long production runs.

Accuracy Checks for Machining Centers and Lathes

Technicians verify machine alignment through parallel and perpendicular measurements on the axes. They also test spindle runout and clamp force to ensure the machine can hold tight tolerances. These checks help confirm the machine is not drifting out of spec and can keep producing accurate parts without rework.

Optional Services to Close Capability Gaps

Some shops choose deeper diagnostic tests. Options include ballbar testing for circularity issues, spindle balancing for smoother finishes, thermal imaging to spot heat-related faults and laser calibration for precise axis compensation. These services help you get your machines back to peak condition if PM uncovers performance gaps.

How PM Reduces Total Cost of Ownership

Proactive maintenance reduces surprise failures, which lowers repair cost and helps keep delivery schedules stable. It also protects warranties, reduces scrap and keeps machines productive longer. That combination plays a major role in strengthening throughput stability and overall equipment effectiveness.

PM Within the Morris Portfolio

The Morris PM program is built to extend machine life and reduce downtime across the entire lifecycle of a CNC machine. Each service visit is designed to restore performance accuracy, protect critical components and keep your production predictable. The result is a stronger return on every machine investment you make.

Conclusion

Annual PM and TPM give shops a reliable way to stay ahead of problems instead of reacting to them. When machines stay accurate, cool, lubricated and aligned, uptime goes up and total ownership cost goes down. A consistent maintenance routine keeps production stable and extends machine life, which is exactly what every shop needs to stay competitive.

Why should our shop invest in Preventative Maintenance (PM)?

PM helps avoid costly downtime, improves machine reliability, extends the life of your equipment, and safeguards warranty validity.

What does Morris’s PM program include?

Our PM covers fluids and filters, cleaning tanks, replacing disposable filters, checking hydraulic, lubrication, air and coolant line assemblies for leaks, and verifying the lubrication system delivers proper lube to ball screws, ways, and linear guides.

How do you handle cooling, airflow and electrical/safety systems?

What checks are done on motion systems, geometry and alignment?

What does TPM (Total Productive Maintenance) add beyond standard PM?

TPM is a more intensive inspection providing detailed performance and repeatability checks. For machining centers, critical parallel and perpendicular geometry measurements are checked. Spindle runout, load and temperature are tested before and after running at max RPM for 30 minutes. Pull-force retention and headstock cleaning also included. For lathes, turret, headstock, and tailstock alignments are verified along with spindle and actuator runout.

Are additional diagnostic services available?

How does PM reduce long-term ownership costs and improve ROI?

Preventative maintenance reduces unexpected machine failures, lowers repair cost, helps avoid scrap due to wear-related accuracy loss, and allows you to budget part replacements. With proper maintenance records, machine resale value is also preserved.